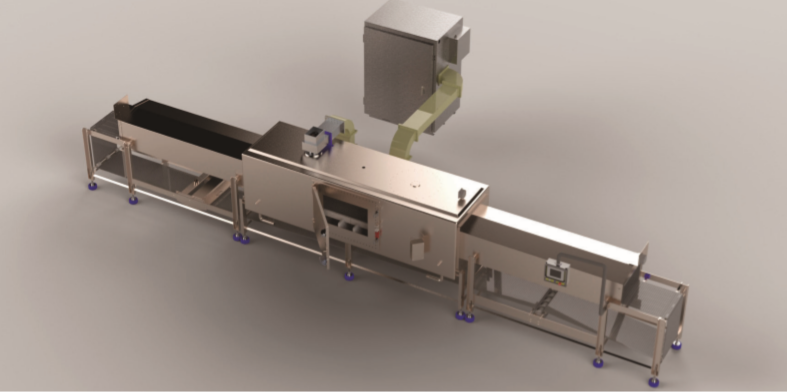

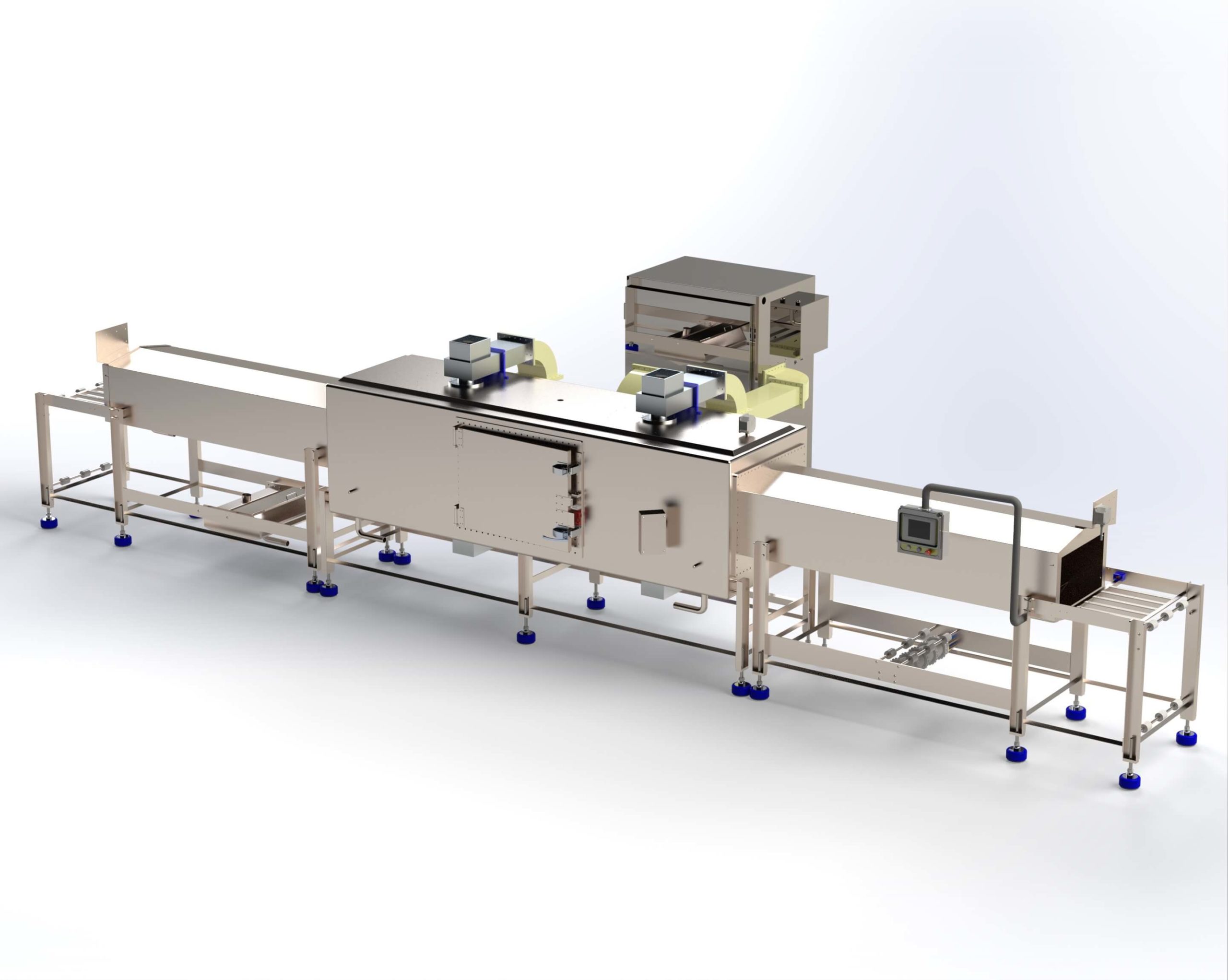

Continuous Tempering Tunnel Model MIT 36

Microwave TechnologyFEATURES

MIT 36 Continuous Microwave Tempering Tunnel

Designed and built by Dantech the continuous microwave tempering tunnel is designed to temper meat, fish, fruit and vegetables typically from -20 to -3 Celsius. The capacity varies according to the product, but typically 2000 kg/h for many products.

Construction & Design: The MIT 36 tempering tunnel is constructed in stainless steel grade 1.4301/AISI 304. Built to comply with CE, AMI and following the EHEDG (European Hygiene Engineering and Design Group) principles for hygiene and best practice.

The all stainless-steel tunnel comes in 3 sections for easy site assembly plus the power supply/transmitter

Overall length = 8830 mm

Height Overall = 2154 mm

Special Features

- Polarized feeds improving uniformity of tempered product optimizing the energy transfer to the product.

- Standard opening: W x H = 610 x 250 mm.

- Allen-Bradley 800 7” PanelView HMI with improved usability with remote monitoring capability.

WaveGen 80 transmitter/Power supply provides up to 75 kW of power, up to 4 transmitters per 3.6m cavity.

Requires 3 phase 50/60 Hz, 400-500 VAC, 110 kVA main supply.

Frequency options: 896 or 915 MHz

DOWNLOADS

Continuous Tempering Brochure Tempering Oven Dimension Drawing MIT 36 Tempering Tunnel SpecificationMAKE AN ENQUIRY

DanTech Engineering manufactures the meat & bacon press, sanitizing tunnels, conveyors and bespoke equipment for the group, combining more than 120 years experience in production, manufacturing and servicing of equipment for the food industry.