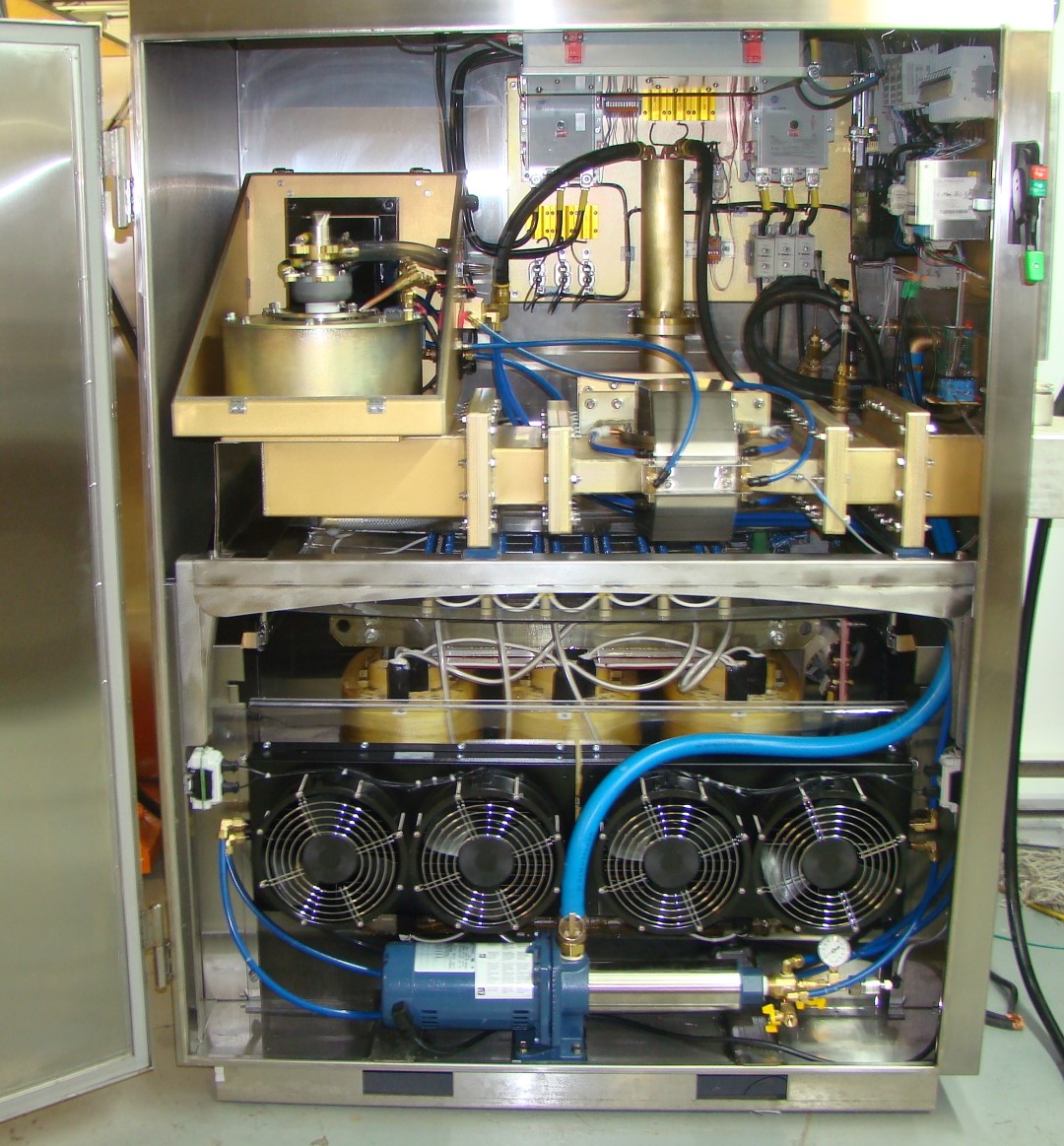

Microwave Power Supply/Transmitter

Microwave TechnologyFEATURES

WaveGen Power Supplies/Transmitters

The WaveGen power supply is available either 75 kW or 100 kW depending upon the application or requirements.

Designed for reliability of service and proven over many years of research and development by the highly trained and knowledgeable team from ThermoWave Technologies, this transmitter has the very latest of built in technology for safety and power stability.

Of the many features here’s what stands out:

- Housed in a stainless-steel cabinetry NEMA 4X/IP66 protection from dust and water splashes.

- Fully Adjustable Power Output of 0-75 Kilowatts or 0-100 Kilowatts.

- Microwave Isolator to Prevent Reflected Power from Damaging the Magnetron.

- Hard-wire Monitored Safety Interlocks.

- Stand-alone, Closed Loop Power Supply Cooling System.

- 24 Volt Control Circuit per IEC Safety Standards.

- High Voltage Lockout for Safe Maintenance Testing of Control Circuits.

- Includes New Magnetron Tube Fully Tested to Operate up to 80KW or 100KW.

- Internal Magnetron EMI Enclosure that Contains RF Leakage to Meet Code Requirements.

- Internally Guarded High Voltage Transformer & Rectifier Assembly.

- Allen Bradley PLC with Ethernet Communication.

- Safety Relay and Dual High Voltage Contactors.

- Reduced Voltage Start (Step-Start).

- Analog Sensors to Measure Forward Power, Reflected Power and Efficiency.

- PLC Controlled, Electronically Driven Filament Transformer and Electromagnet Design Provides State-of-the-Art Magnetron Power Control.

- Improved Water System for better distribution for magnetron cooling components.

Utility Requirements;

Power: 400-500 VAC, 3 phase 50/60 Hz,125 FLA, 175A minimum circuit breaker.

Cooling water: >40 l/min, download chart.

Dimensions:

W x D x H = 147.5 x 95.5 x 183 cm

Mass: 1360 kg

DOWNLOADS

Power Supply/Transmitter cooling chart. Dimension DrawingMAKE AN ENQUIRY

DanTech Engineering manufactures the meat & bacon press, sanitizing tunnels, conveyors and bespoke equipment for the group, combining more than 120 years experience in production, manufacturing and servicing of equipment for the food industry.